E2U's One Day Garage System

It's never been easier or faster to install beautiful garage flooring!

The E2U One Day Garage System offers a fast, simple, and cost-effective solution to safeguarding and refurbishing your garage floors. Utilizing high quality components, our system ensures greater durability and affordability than ever before. Plus, with our rapid cure line of products, you can complete an entire garage floor in one day. Shop products from our One-Day Garage System Here.

Important Note: Color Shades May Vary Depending On The Screen Or Monitor You Are Viewing This Chart On

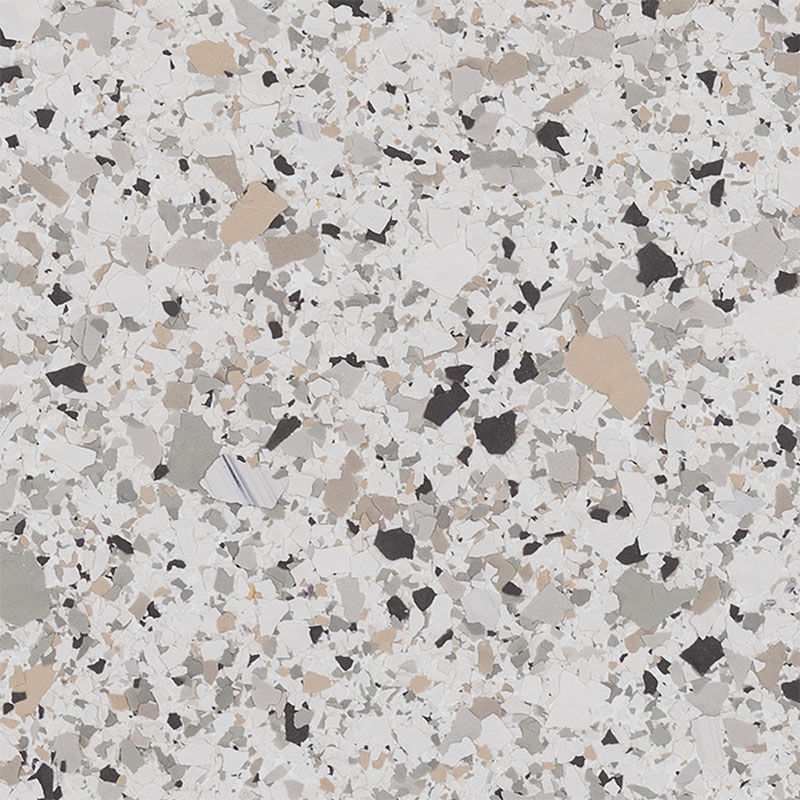

Stone Flake Series

Important Note: Color Shades May Vary Depending On The Screen Or Monitor You Are Viewing This Chart On

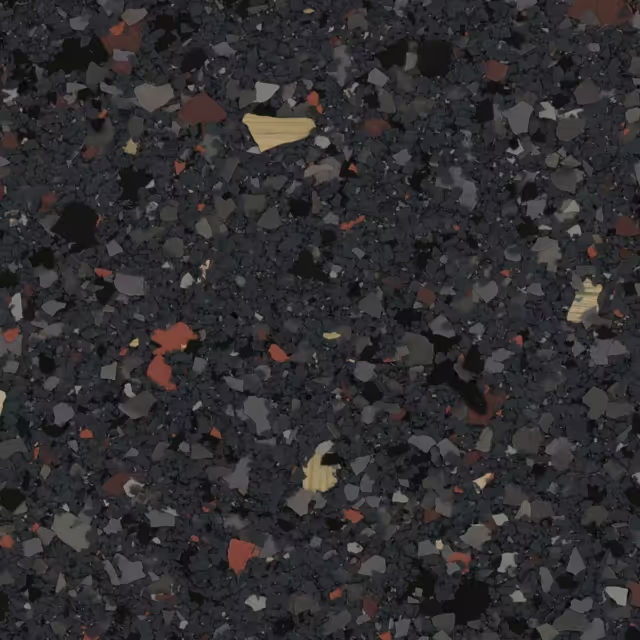

BLACKTOP

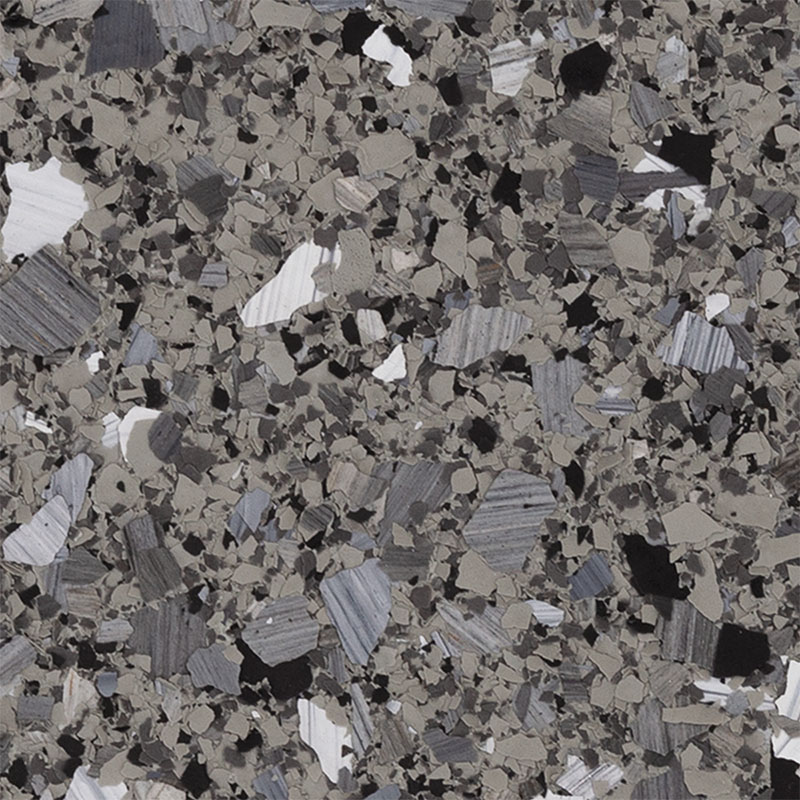

SLATE

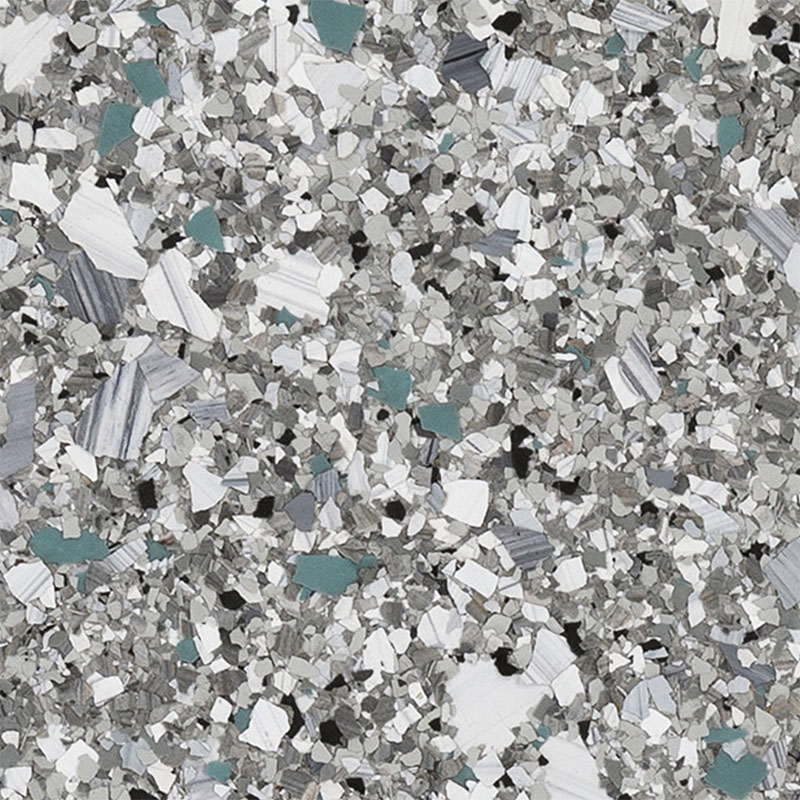

TURQUOISE

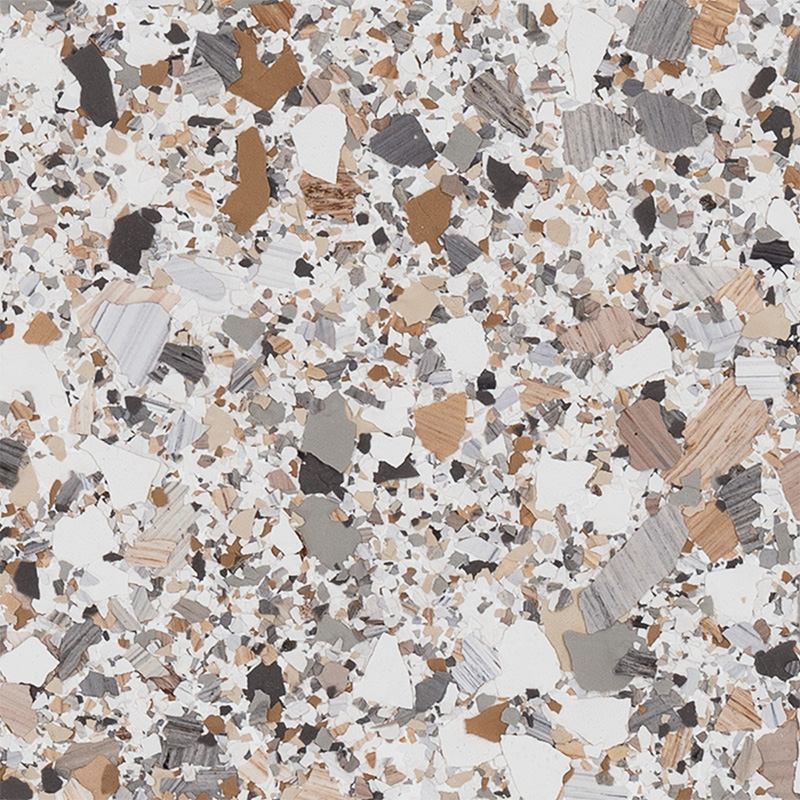

SHALE

QUARTZITE

BLUE GRANITE

CLAYSTONE

LIMESTONE

Stone Flake Colors Available Upon Request

Shop Our One-Day Garage Flooring System Products

What makes E2U's One Day Garage System the best in the business?

Shop Our One-Day Garage Flooring System Products

Shop Our One-Day Garage Flooring System Products

Send us a message today!