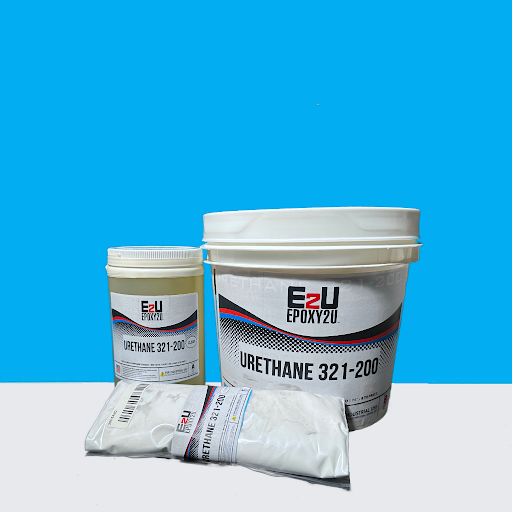

E2U Urethane 321-200 is a three component aliphatic urethane floor finish. It exhibits excellent characteristics for abrasion and chemical resistance, flexibility, weathering, and UV stability. The combination of 1 part A, 3 parts B, and C components will l result in a satin (semi-gloss) finish. It must be applied at 4-5 mm thickness. Coverage: 550-600 sq. ft./gal.

Coverage:500 – 600 SF/Gal – This particular sealer actually MUST be rolled out at the specified coverage rate… going less can cause white spots, small clumps, and unevenness.

NOTE:This sealer is designed to ONLY be applied to smooth flat surfaces, i.e.: Over epoxy, or concrete that has been primed w/either a Waterbase or 100% Solids Epoxy or stained with WB Acrylic Stain… NOT Acid or Acetone based stain. Do not apply directly to bare concrete.

Urethane 321

E2U Urethane 321-200 is a three component aliphatic urethane floor finish. It exhibits excellent characteristics for abrasion and chemical resistance, flexibility, weathering, and UV stability. The combination of 1 part A, 3 parts B, and C components will l result in a satin (semi-gloss) finish. It must be applied at 4-5 mm thickness. Coverage: 550-600 sq. ft./gal.

Coverage:500 – 600 SF/Gal – This particular sealer actually MUST be rolled out at the specified coverage rate… going less can cause white spots, small clumps, and unevenness.

NOTE:This sealer is designed to ONLY be applied to smooth flat surfaces, i.e.: Over epoxy, or concrete that has been primed w/either a Waterbase or 100% Solids Epoxy or stained with WB Acrylic Stain… NOT Acid or Acetone based stain. Do not apply directly to bare concrete.